With inspiration coming from Australian Supercar and GT3 racers, the Next Gen modernizes the Cup car, which has evolved at a snail's pace since the series formed in 1948. Even fuel injection wasn’t implemented until 2012.

Here we'll cover the assorted changed for the next version of the NASCAR race car.

Read on to see the changes and pictures.

Car Specifications are at the bottom

Body and Aerodynamics

The most obvious change to the Next Gen cars is visual. NASCAR has enabled the teams to shape the bodies to more closely resemble the production cars they are named after. The overall profiles and noses will better represent the street-going versions of the Toyota, Chevrolet Camaro, and Ford Mustang. Once the teams submit their designs, NASCAR then verifies that they meet their stringent aerodynamic requirements. One factor greatly complicating the task is that while the three bodies may look different from each other, they must be similar in aerodynamic properties in order to maintain a level playing field in competition.

The bodies will also be symmetrical. In previous generations, the passenger side protrudes out farther than the driver's. This has allowed the body to create more side force. Currently, the Cup bodies are constructed of sheet metal. The carcass of the Next Gen car, such as the Xfinity Series cars, will be assembled with carbon-fiber-reinforced plastic panels. The carbon-fiber bodies are more flexible and durable, meaning an unpleasant interaction with another driver or an intimate encounter with the wall will have fewer consequences. They will also be cheaper for teams to repair by only requiring a panel to be replaced rather than an entire body side.

Dimensionally, the body has shrunk. The 50.4-inch roofline sits roughly 1.5 inch lower than before, and shortening up the decklid has removed 6.0 inches from the overall length. At 78.6 inches, the body is 1.6 inch wider, and the wheelbase remains the same at 110.0 inches.

Aerodynamically, the front splitter and rear wing will always be dictated by NASCAR to limit how much downforce a car can generate, while at the same time limiting speed. However, two big changes are happening with the Next Gen car.

Previously, teams would engineer any exposed element on the underside to make them more aerodynamic or to provide some downforce. This gets costly, and some of the smaller teams lack the budget to develop these parts. Now, the underside of the car features carbon-fiber undertrays to create a flat surface, removing the need to develop those parts, and to smooth out the air that will flow through rear diffuser—a first for NASCAR.

These carbon fiber undertrays reduce costs by eliminating the need to engineer exposed elements on the underside to make them more aerodynamic.

Teams spent a lot of money to do that up until now and outfits that didn't have the funds to do it had to cope with inferior aerodynamics. As with the other aerodynamic elements, NASCAR will change the diffusers based on what track they are running. The hood now features NACA ducts to help extract heat. Additionally; the car number on the doors are being moved ‘forward’ close to the front wheels. This move allows for more sponsorship room. The Next Gen car will allow cars to feature chrome/metallic number designs as opposed to the traditional glossy finish the number stickers have had.

Chassis

Previously, raw steel tubing would enter a race shop at one end, and a tube frame would exit the other. That is no longer the case. Michigan based Technique Inc. will provide all the frames, which now consist of a common center cage with bolt-on front and rear substructures. Michigan based Technique Inc., is owned by former Indy Racing League driver Ronnie Johncox. The idea here is that when an inevitable crash occurs, the bolt-on

structures can be replaced rather than cutting up or throwing away an entire tube frame, and in turn, this should help reduce operating costs.

Goals here, we can surmise, include reduced fabrication costs and smaller fab crews for the race teams. If it works out, teams could be building fewer race cars each year and getting more seasons out of them as well. While the new cars are slightly wider, wheelbase is the same and overall length remains similar. Weight is 3300 lbs.

The current car relies on a single-adjustment damper to absorb high-speed abnormalities on the

race circuits. The race haulers are filled with dampers for engineers to choose from and then fine tune, while also choosing the correct spring rate. That will be no more. NASCAR has tapped Öhlins to provide a four-way-adjustable damper at all four corners. This will allow teams to tune a single unit for various tracks, with the potential for making adjustments on pit lane. As before, which springs are selected will be track dependent.

Front and Rear End

Up front, billet aluminum control arms will locate the wheels, but in the rear is where a much-needed, long-awaited, and quite possibly the biggest change is occurring. Currently, the car rides on a live axle in the rear, located by two trailing arms. The Next Gen marks the change to an independent rear suspension. The multi-link configuration allows more adjustment and will pay dividends on road courses, which NASCAR continues to add to the schedule. The in-car driver adjustments to the track bar (the side-to-side movement of the rear axle) are removed, but the wedge (rear spring tension) will still be adjusted on pit lane by dropping a wrench through the rear window. the current car still uses a recirculating-ball steering box. This ancient technology dates back to the start of stock-car racing and can be found

on a Jeep Wrangler or Gladiator. The move to a rack-and-pinion steering system brings the car up to modern standards.

Drivetrain

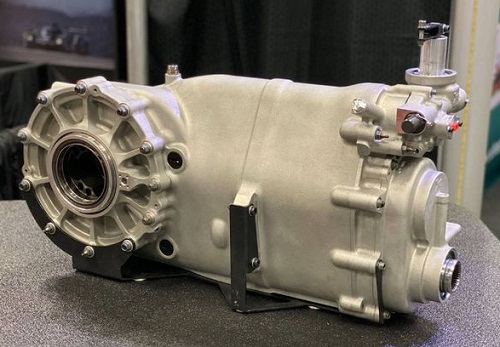

Thankfully, NASCAR has made no changes to the heart of these cars. Under the hood, the pushrod V-8 engines from Chevrolet, Ford, and Toyota will still be limited to 358 cubic inches and capped at 550 horsepower for restrictor plate racing and 670 hp for the tracks. Whereas the current car features a crossover pipe so that all eight cylinders bark their glorious tone at the fans, the new undertray required a change to how the exhaust is routed. Each bank of cylinders will now exit from the left or right of the car, meaning you might only hear an inline-four from the stands. We’ll save our judgment until we hear the car ourselves. In transmission news, the four-speed H-pattern gearbox is replaced by an X-Trac–supplied six-speed transaxle. (XTrac P1334). Now when changing the gears, instead of the driver making the H-pattern moves; they

The arrow points toward the new shifter

will just bump the shifter forward to backward to shift the transmission up or down. Picture on right has arrow pointing toward new shifter. The engineering departments say that we won't see any downshifting at the high-speed ovals, as NASCAR's final-drive selections will make sure that doesn’t happen, but the additional gearing will provide more gear swaps when the series visits road courses. The details on the transmission are hard to explain, so here is a video that shows you what it looks like, how they tear it down. Gear ratio changes with the transaxle are accomplished with drop gears, allowing race teams to eliminate the enormous inventories of transmission gearsets and rear axle pumpkins they must currently keep on hand to provide the proper gearing for each race track. The transaxle also supports NASCAR’s first independent rear suspension, employing twin wishbones and coilover dampers, and it also enables an easy changeover to hybrid and full-electric powertrains when the time comes. Part of NASCAR's mission was to develop a platform that can be adapted over time, and the transaxle supports that strategy.

Wheels, Tires, and Brakes

A major part of a NASCAR race is the show that occurs on pit lane. The impeccably orchestrated tire-changing sequence where high-rpm air guns wail away at five lug nuts per wheel can make or break a race. The old 15-inch wagon wheels will be sent to pasture with the introduction of the Next Gen and be replaced by a BBS supplied 18-inch forged aluminum wheel. The change to a center-lock wheel met the most pushback from teams, but it was required because of the destruction the 10,000-rpm air gun would cause each time it is was slammed against the aluminum wheel. The move to a center-lock wheel better aligns the Cup series with any other noteworthy racing class. NASCAR claims that due to the speed and the weight of the cars, the center lug has more clamping force than any other series. The wheel change will certainly make for quicker pit stops but provide far less drama. With the larger wheels comes a new tire. The Goodyear Eagle race rubber

New 18" tall wheels

New 12" wide tires

gets wider, growing from a 305-section width to a 365, and has a shorter sidewall. The 18-inch wheel also opens the door for bigger brakes, measuring 15.0 inches in the front and 14.0 inches in the rear, up from current 12.7-inch rotors at the front and rear. The new brakes will be made by AP Racing. There will be two rotors to choose from, both having the same diameters but different thicknesses. A narrower rotor will be used for high-speed ovals, while a thicker rotor will be tasked to manage the higher thermal loads of short tracks and road courses. The clamping forces will be provided by a six-piston caliper in the front and a four-piston out back. I used the picture below to point out something above. But in this picture I wanted to points out the brakes, and also the air ducts. The large (orange) duct is just force driven. While the small duct has a fan (the white thing). The more teams have to keep brakes cool, the more brake ducting we'll see, and usually more are fan driven. Other upgrades include

a NASCAR-spec underbody and rear diffuser designed to discourage competitive advantage in that area and reduce the dreaded “aero push” (a tricky problem that sometimes makes passing nearly impossible). Reinforced front and rear bumper supports and a comprehensive energy-absorbing foam cell system will contribute, NASCAR hopes, to the safest Cup cars in history. The steering is a rack and pinion CF unit from the Woodward Machine Corporation. McLaren Automotive will provide the onboard electronics and driver display, and improved connectivity has been baked in to provide the fans at home with more in-car data. Really, the only major components that aren’t new are the engines. They’re still 358 CID, fuel-injected, pushrod V8s provided by Toyota, Ford, and Chevrolet, respectively, and currently regulated to 550 hp to 670 hp depending on the track. They don’t resemble any current production engines from the three carmakers, but they do resemble each other a great deal—due to the tight confines of the regulatory

Brakes and air ducts ABAB

box NASCAR has defined for them. Clearly, there are two main goals for the Next-Gen race car: Reduce operating costs for the teams, and improve the entertainment value of the show for the fans. When the new cars roll out at Daytona next February to kick off the 2022 NASCAR season, we’ll begin to see well the ambitious plan is working out. On paper and in photos, the cars look spectacular. The changes to the all-new car are impactful, but the biggest question remains: How will the cars race? That we will not know until they make their debut in 2022 at Daytona International Speedway. We can only hope for some exciting racing as NASCAR is motorsports first, entertainment second.

SPECS

LENGTH - 193.4”

WIDTH - 78.6”

HEIGHT - 50.4”

WHEELBASE - 110”

WEIGHT - 3300

SPOILER – changes based on track

BODY – Composite symmetric body featuring integral flap systems, camera mounts and OEM-specific design elements

UNDERWING – Full carbon undertray with center stepped splitter and rear diffuser

CHASSIS – Steel tubing with bolt on front and rear clips; and front and rear bumpers

TRASAXLE – 6-speed manual sequential with ramp and plate differential

SUSPENSION (front and rear) – Double wishbone billet aluminum control arms with adjustable coil over shock absorbers.

STEERING – Rack and pinion

WHEELS – 18” x 12” forged aluminum

TIRES – Goodyear Eagle

BRAKES – 6 piston monobloc front calipers / 4 piston monobloc rear calipers

FRONT BRAKE ROTORS – 15”

REAR BRAKE ROTORS – 14”

ENGINE DISPLACEMENT – 358 cubic inches

INDUCTION SYSTEM – Naturally aspirated

FUEL SYSTEM – Fuel injection

OIL SYSTEM – Dry sump

HORSEPOWER – to be determined based on track

ENGINE COOLING – Air exits radiator through hood louvers

EXHAUST – Split-side exit exhaust

FUEL CELL – 20 gallons